We use cookies to make your experience better. Read more

- - January 02, 2024

JTC Valve Sales is an authorized reseller of industrial gas valves. JTC Valve Sales possesses years of experience in serving various industries with high-quality, durable, and performance-efficient valves.

- - January 02, 2024

McGraw Edison Transformer has a history. Max McGrow found a company – ‘McGrow Electric’, which was in the business of installing electricity in houses. Gradually, they expanded to industrial & commercial buildings and through the years

- - January 02, 2024

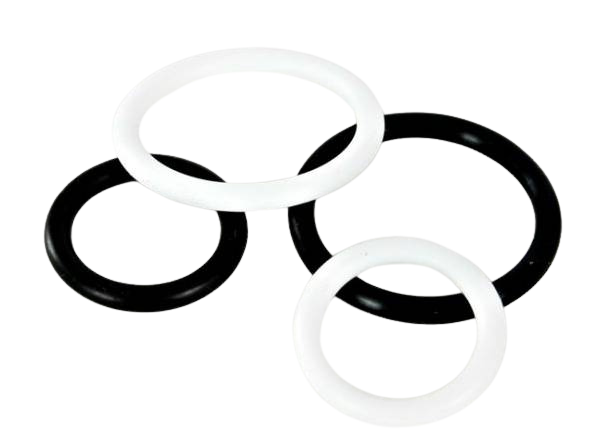

An O-ring seal is a seal made of an elastomeric O-ring and a gland intended to prevent the loss of fluid or gas from within the cylinders. The assembly consists of the doughnut-shaped ring – circular cross-section

- - January 02, 2024

Specialty Valves are really dominating the valve industry as the flawless specifications they adhere to are difficult to attain.Sherwood Valves is a trusted manufacturer of such high-quality

- - January 02, 2024

Safety of compressed gas cylinders is essential for maintaining the industrial standards of safety. Fastest compressed gas products are manufactured in the USA and adhere to strict quality and

- - January 02, 2024

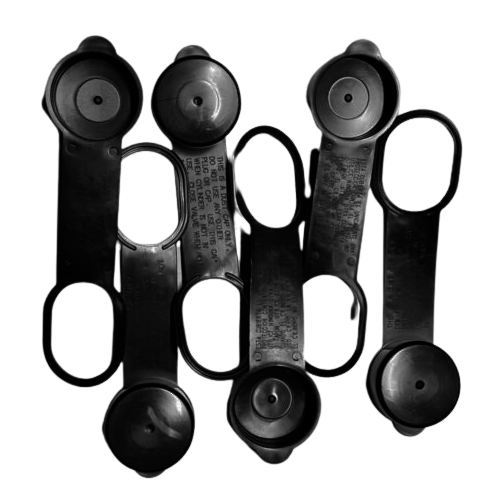

Some people have the innate ability to blow up balloons with ease. Frankly, we are not these people! However, balloon inflators help.

- - January 02, 2024

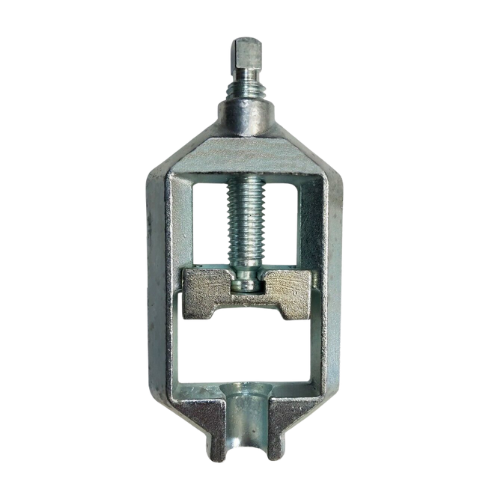

Needle valves are a much-needed kind of valve in every gas industrial set up. The valves closely resemble globe valves in design and function except that they have a pointed end instead of the disk at the end of the valve system.

- - January 02, 2024

Ammonia, in its various amounts of dilution, is a dangerous element. Anhydrous ammonia is classified as a toxic gas for the environment. It can form explosive mixtures upon reaction with air (16-25%)

- - January 02, 2024

Fusible plugs are used to keep the temperature of the fusible metal below its melting point. The fuse plugs operate as a safety valve when abnormal or dangerous temperatures build up in a closed vessel.

- - January 02, 2024

In the past, hoses manufactured with rubber were designed for hydraulic uses. But when these hoses were exposed to carbon dioxide, they could not hold out against deterioration. On inspecting reasons for this,